ADVANCED TECHNIQUES FOR BUILDING-BLOCK INTERCONNECT LAYOUT DESIGN:INTERCONNECT ROUTING.

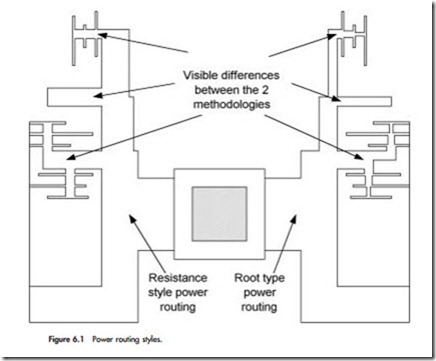

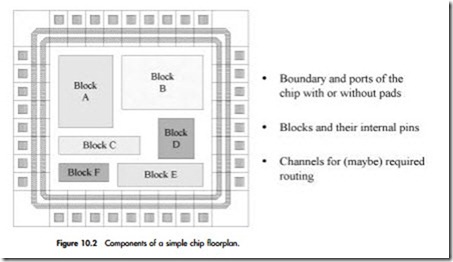

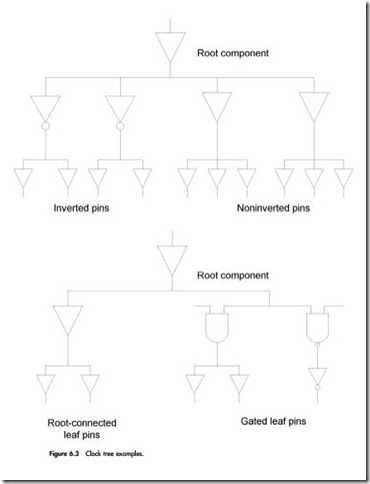

INTERCONNECT ROUTING After we have solved power routing and clock tree issues, we can attack the general routing requirements. Special signal requirements will be discussed in Chapter 7. Let’s review the proper order for routing signals: 1. Power supplies 2. Clock signals 3. Buses 4. Special signals—to be discussed in Chapter 7 5. General routing—the topic of this section Routing Plan The goal of a routing plan is to determine the overall complexity of the routing to be implemented, identify areas on the die specifically for routing only (these areas are known as routing channels), and address potential bottlenecks or prob- lems in achieving a completely routed design. In addition, the impact of the routing on the final chip area can be estimated. For example, dedicated routing channels can be estimated and included in a chip floorplan. Here is a list of steps to achieve a viable routing plan. 1. Signal Estimate. Without a final schematic or netlist, it is