Variable resistors,Capacitors and Inductors

Variable resistors

Variable resistors are manufactured in a similar manner to fixed value resistors. Low wattage variable resistors use a carbon track over which a slider is moved.

High wattage variable resistors, on the other hand, are usually wire wound. Both types have inherent problems; carbon variable resistors tend to produce dirt on the track and are prone to track breakage, whereas wire wound versions need many turns to give adequate resolution.

Tracks based on a fused metal/glass material (called cermet, an abbreviation for ceramic/meta!) have greatly superior characteristics to both carbon and wirewound types, and are increasingly used in industry.

Variable resistors are available in linear, logarithmic or anti logarithmic forms. The first has a simple linear relationship between slider position and the resistance value. Logarithmic and anti logarithmic variable resistors, on the other hand, follow a log curve,and are used, for example, as volume controls or balance controls in audio equipment, in an attempt to compensate for the peculiar response of the human ear.

Resistor and capacitor letter and digit code

(BS 1852)

Resistor values are indicated as follows:

Capacitors

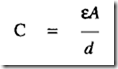

The construction of capacitors is governed by the equation:

Where A is the area of the plates of the capacitor, E is the permittivity of material between the plates, and d is the separation of the plates.

A simple parallel plate capacitor construction following this is illustrated in (a).

In general, the capacitance of parallel plates is inadequate for practical circuits. For example, two plates of I 00 cm2, separated by I mm, would have a capacitance of around 80 pF. The design of high value capacitors is achieved by increasing plate area A and permittivity E or by decreasing plate separation d.

Unfortunately, capacitors need to work at quite high voltages and this presents the component manufacturers with conflicting requirements.

Resistor and capacitor letter and digit code

(BS 1852)

Capacitors

The construction of capacitors is governed by the equation:

Where A is the area of the plates of the capacitor, E is the permittivity of material between the plates, and d is the separation of the plates.

A simple parallel plate capacitor construction following this is illustrated in (a).

In general, the capacitance of parallel plates is inadequate for practical circuits. For example, two plates of I 00 cm2, separated by I mm, would have a capacitance of around 80 pF. The design of high value capacitors is achieved by increasing plate area A and permittivity E or by decreasing plate separation d.

Unfortunately, capacitors need to work at quite high voltages and this presents the component manufacturers with conflicting requirements.

Practical capacitors are often constructed by means of interleaved metal foil and high permittivity dielectrics such as mica or ceramic materials, as shown in (b). An alternative method is to evaporate metallic films directly on to the dielectric. This method of construc tion gives a stable capacitor (known as a silver mica capacitor) with good characteristics. Capacitors can be constructed with values from a few pF to around 5000 pF.

Larger values of capacitance can be produced by using foil and paper in alternate layers. There are many variations on the design of foil capacitors, using different materials for the dielectric. Polyester and polycarbonate dielectrics are used in capacitors of the same name.

To obtain large values of capacitance it is necessary to reduce separation of the plates further. This can be achieved by immersing a metal plate in an electrolyte. A thin oxide film forms which behaves as a dielectric between the 'plates' of the metal and the electrolyte. The plate/oxide/electrolyte thus exhibits the properties of a capacitor, and the exceptionally thin oxide layer (typically J0-4 mm) ensures that the value is high.

A further increase in capacitance can be obtained by etching the metal plate. This roughens the surface, thereby increasing the surface area. There are many variations on the basic ideas of electrolytic capacitors, the latest of which is the use of tantalum. Tantalum oxide has very high permittivity, and tantalum electrolytics are small, stable and have very low leakage current. Compared with other electrolytics, however, their working voltage range is very limited, typically 10-20 volts.

Electrolytic capacitors always operate with a standing DC voltage across them. If the voltage is reversed in polarity, the dielectric oxide film breaks down. Gas can then be formed in the electrolyte, building up an internal pressure which can rupture the casing of the capacitor. It is therefore very important to ensure that electrolytics are always used with the correct polarity across them.

In general, electrolytics are not good capacitors. Compared with conventional capacitors their power factor is poor, they exhibit high leakage and are quite expensive. They have a short life and tend to dry out in high ambient temperatures. Consequently, electrolytic capacitors are tolerated only where other types of capacitor cannot be used.

All types of capacitor have a maximum working voltage specified. This can range from a few volts for a tantalum electrolytic to several kilovolts for specialised paper capacitors. The circuit must be analysed to find the peak voltage (not RMS) likely to occur (including transients) and the capacitor specified accordingly.

Variable capacitors are required for tuned LC oscillators. The capacitance can be varied by adjusting A, d orE in the earlier equation. Variable area types use an air dielectric and two vane sets whose relative angular position can be adjusted. Trimmer capacitors often vary separation d of sprung plates. Variable dielectrics are not widely used, but are sometimes found in instrumentation transducers, where a displacement is converted to a capacitance change by the insertion of a dielectric material between two fixed plates. The change in capacitance in all devices is small (typically a few hundred pF). Increasingly, variable capacitance is obtained with varicap diodes, described later.

Inductors

Inductors are generally used as part of a tuned LC circuit in oscillators or RF circuits. It is therefore important to have stable inductors of a reasonable size.

For relatively low value inductors a single layer of wire around a

former will suffice. To get higher values, however, it is necessary to use multilayer coils, although these do tend to have a high value of stray capacitance.

Where several inductors are used in a circuit, magnetic coupling exists between the coils. This can produce undesirable effects such as amplifier instability. If a coil is enclosed in a can, eddy currents are induced in the can material. These eddy currents themselves produce a magnetic field in opposition to the field from the coil. This reduces the field in the coil slightly, but reduces the field outside the can to zero.

Ferrite cores are often used to produce inductors of larger values; this allows fewer turns of wire to be used for a given inductance. Adjustable inductors are also implemented by using a movable iron core. As the iron slug is moved, the permeability of the magnetic circuit, and hence the inductance, is altered. The variation in inductance that can be achieved is only a few percent, which is adequate for trimming a tuned circuit. Where coarse changes are required it is usual to switch inductors.

Inductors of value greater than I H are sometimes used for smoothing in power supplies, although these are less common nowadays. These inductors are known as chokes, and are constructed around laminations in a similar manner to that employed for transformers.

In general, electrolytics are not good capacitors. Compared with conventional capacitors their power factor is poor, they exhibit high leakage and are quite expensive. They have a short life and tend to dry out in high ambient temperatures. Consequently, electrolytic capacitors are tolerated only where other types of capacitor cannot be used.

All types of capacitor have a maximum working voltage specified. This can range from a few volts for a tantalum electrolytic to several kilovolts for specialised paper capacitors. The circuit must be analysed to find the peak voltage (not RMS) likely to occur (including transients) and the capacitor specified accordingly.

Variable capacitors are required for tuned LC oscillators. The capacitance can be varied by adjusting A, d orE in the earlier equation. Variable area types use an air dielectric and two vane sets whose relative angular position can be adjusted. Trimmer capacitors often vary separation d of sprung plates. Variable dielectrics are not widely used, but are sometimes found in instrumentation transducers, where a displacement is converted to a capacitance change by the insertion of a dielectric material between two fixed plates. The change in capacitance in all devices is small (typically a few hundred pF). Increasingly, variable capacitance is obtained with varicap diodes, described later.

Inductors

Inductors are generally used as part of a tuned LC circuit in oscillators or RF circuits. It is therefore important to have stable inductors of a reasonable size.

For relatively low value inductors a single layer of wire around a former will suffice. To get higher values, however, it is necessary to use multilayer coils, although these do tend to have a high value of stray capacitance.

Where several inductors are used in a circuit, magnetic coupling exists between the coils. This can produce undesirable effects such as amplifier instability. If a coil is enclosed in a can, eddy currents are induced in the can material. These eddy currents themselves produce a magnetic field in opposition to the field from the coil. This reduces the field in the coil slightly, but reduces the field outside the can to zero.

Ferrite cores are often used to produce inductors of larger values; this allows fewer turns of wire to be used for a given inductance. Adjustable inductors are also implemented by using a movable iron core. As the iron slug is moved, the permeability of the magnetic circuit, and hence the inductance, is altered. The variation in inductance that can be achieved is only a few percent, which is adequate for trimming a tuned circuit. Where coarse changes are required it is usual to switch inductors.

Inductors of value greater than I H are sometimes used for smoothing in power supplies, although these are less common nowadays. These inductors are known as chokes, and are constructed around laminations in a similar manner to that employed for transformers.

Comments

Post a Comment