Liquid crystal displays, Lasers , Photocell applications and Opto-isolation.

Liquid crystal displays

Liquid crystal displays (LCDs) are unique display devices, in that they require minimal power to operate. This makes them very popular for battery-powered devices such as calculators and digital watches.

LCDs are based on materials which exhibit regular crystal-like structures even in a liquid state. The material is normally transparent, but if an external electric field is applied, complex interactions between the internal molecules and free ions cause turbulence in the crystal. The liquid then turns an opaque milky colour.

In it simplest form an LCD cell consists of two glass plates separated by insulating spaces. The gap between the plates is filled with the liquid crystal, as shown. When an electric potential is applied across the plates, the cell becomes opaque.

An LCD cell can be used in either of the two modes shown in (a) and (b). Transmissive mode (a) requires an integral light source. Reflective mode (b) uses incident light.

Obviously the reflective mode can only be used in good ambient light levels, but its exceptionally low current requirements (typically I ) make it almost mandatory for battery-powered circuits.

LCDs operate on a few volts, making them a natural companion to low power CMOS. Although LCDs will operate on DC their life expectancy is reduced by polarisation effects. This can be overcome by driving the cell segment and back-plane from a simple square wave generator. A circuit commonly used is shown.

Lasers

Lasers are commonly thought of as a kind of death ray, and have been described by some engineers as a solution in search of a problem. Over the past few years, however, lasers have been emerging from the laboratories to become a useful tool for industry.

Light from a laser differs in two respects from light from a normal source. Firstly it is absolutely monochromatic; it consists of light of only one frequency. Secondly it is coherent. This term requires some explanation.

All light (because it is a fonn of electromagnet radiation) is wave like in nature. Light from conventional sources is emitted with random phase, as shown in (a), so even if it is monochromatic some cancellation will occur. All the light from a laser, however, is exactly in phase, as in (b), and reinforces rather than cancels.

If an atom absorbs energy, say from being heated, electrons move out to larger radius orbits. The atom is then said to be in an excited state. Eventually the electrons return to a lower orbit, releasing energy in the fonn of a packet of light called a photon. Because the electron orbits are fixed, only certain energy gains and losses are allowed.

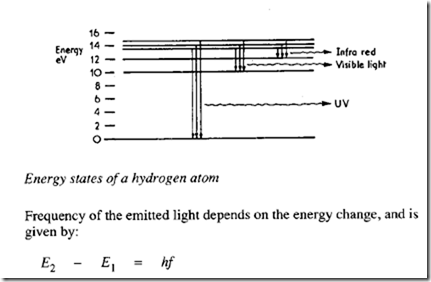

Possible energy states for hydrogen are shown; a minimum of 10 eV is required to lift it to state 1.

where E 1 and £2 are the energy states,[ is the frequency and h is Planck's constant.

When a substance is heated, atoms are continually excited into higher states, and falling back. Each transition, from higher state to lower state and from high states to base state, emits a different wavelength. We perceive the combination of all these as the object glowing.

Laser light, however, arises from just one transition, hence its monochromatic nature. A typical laser, shown in (a), consists of a ruby rod surrounded by a flash tube. The ends of the rod are machined parallel. One face is silvered to a mirror finish, and the other half-silvered.

To start laser action it is necessary to get more atoms into an excited state than remain in the ground state. This is called a population inversion, and is obtained by firing the flash tube (called pumping). Ruby has the energy states shown in (b). There is a state I at 1.8 eV above the base state, and several hundred closely spaced states forming a band just above state I. Pumping takes a majority of the atoms into the energy band from where they fall back spontaneously into state I. Here they are transiently stable.

Eventually (after a few microseconds) an atom returns to the ground state, emitting a photon as it falls. This photon strikes other excited atoms and triggers their return to the ground state. These also emit photons which are exactly in phase with the originator. A chain reaction effect now takes place, with a rapidly intensifying pulse of light reflecting up and down the tube, all photons in phase.

Eventually a brief intense pulse of light, lasting about a millisecond, emerges from the half-silvered end of the tube.

The energy difference between state I and the ground state is 1.8 eV, which from the above equation corresponds to a wavelength of 6943 A; that is, in the red part of the spectrum.

The ruby laser shown is called a pulsed laser, for obvious reasons.

It is not possible to operate it continuously, as a permanent population inversion cannot be achieved. To get continuous laser action a four-level system is used, as shown below. Atoms are excited into the high energy band, from which they fall spontane ously to state 2. Laser action takes place between states 2 and I, from which atoms return spontaneously to the ground state. Laser action occurs if there is a population inversion between states 2 and I and this is achievable with relatively low pumping energies. Continuous lasers are less powerful than pulsed lasers.

Laser applications are based on a laser beam's monochromaticity, its tight beam (a laser beam spreads by less than 0.001 radians) and its high concentration of power (because a laser beam is very narrow the energy is concentrated on a small area). Typical uses include accurate level-setting in civil engineering, and precision cutting and trimming (the lack of a flame means no contamination of the object being cut). Precision distance measurement can be made by interferometry techniques because of the monochromatic nature of laser light. Distances from a few millimetres to thousands of kilometres can be measured to a high degree of accuracy.

Photocell applications

A photocell is a device for detecting the presence (or absence) of an object by means of a light beam. Typical applications are counting of objects on a conveyor belt, burglar alarms and sequencing of automatic control.

There are basically three types of photocell:

(I) transmitter/receiver

(2) reflector

(3) incident light.

The transmitter/receiver uses a separate light source and photocell, as shown in (a). The object to be separated breaks the beam. By careful design, beam lengths of over 1000 m can be obtained, although alignment can be a problem.

A reflector system is shown in (b). The beam is a double (out and back) beam with an external mirror and an integral light emitter/ sensor. This arrangement is simple to install. The mirror is usually a prismatic type (similar to rear reflectors on motor cars) to simplify alignment.

A second type of reflector system uses light reflected off the surface of the object to be detected. This is shown in (c). This obviously requires the object to have a reflective surface, and the range is limited to a few centimetres.

The final type of photocell uses light from the object itself, shown in (d). A typical application using incident light is the tracking of red hot billets of steel in a rolling mill.

Most sensor devices are temperature-sensitive, and this presents problems for the design of a stable photocell system. In addition, photocells are often required to operate in high ambient light levels that vary considerably, so a simple DC coupled amplifier/trigger circuit will not work reliably.

Most photocell systems use a modulated light source, usually at a frequency of a few kilohertz. This can easily be obtained by turning the transmitter on and off rapidly.

The receiver comprises an AC-coupled bandpass amplifier tuned to the modulating frequency, followed by a rectifier and DC level trigger. A typical circuit is shown. The circuit responds to light modulated at the correct frequency, and the AC amplifier ensures that it is unaffected by temperature changes.

Opto-isolation

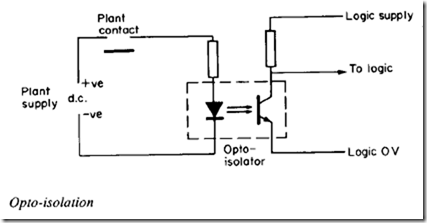

The designer of a logic scheme can face problems with noise if he is required to interface with equipment remote from the logic panel. In addition, there is always the possibility that some external fault will introduce mains voltages into the logic. These problems can be almost totally overcome by the use of opto-isolators.

An opto-isolator consists of a light-emitting diode and phototransistor coupled in one package, as shown. The operation is obvious, and the complete electrical isolation gives excellent protection from common mode noise.

Opto-isolators are normally used for digital inputs and outputs (e.g. push buttons, limit switches, and so on), but it is possible to use them for isolation of linear signals by encoding the analog signal into some digital form (e.g. pulse width or pulse code modulation).

An opto-isolator is specified by its isolation voltage (usually 1- 2 kV) and its current transfer ratio, defined as the ratio of phototransistor current to LED current. This is typically 20%, although higher values can be obtained by the use of photodarlington transistors.

Opto-isolators are quite fast devices, allowing data transmission to

take place at frequencies of over 100 kHz.

Comments

Post a Comment