The p-n junction

The p-n junction

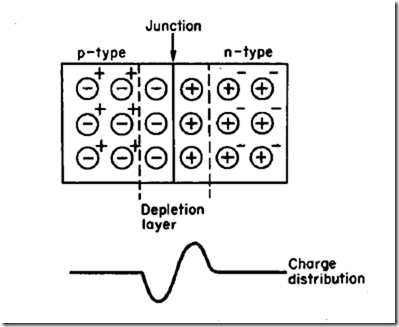

A crystal is shown, one half of which has been doped to form n-type material, and the other half to form p-type material. At the junction, holes pass into then-type and electrons into the p-type material, until a voltage is built up across the junction. This is called a depletion layer, and with no current carriers in the region it forms an insulator.

The p-n junction

The build-up of charge at the depletion layer is a localised effect, and no voltage is detected across the ends of the p-n junction. If, however, a positive voltage is applied from p to n, as shown below in (a), positive holes flow across the junction from p ton, and electrons from n to p. Current is flowing and the device is conducting.

If a negative voltage is applied from p to n, as shown below in (b), a few electrons and holes are removed, but the effect is to increase the depletion layer. After a very short current flow (equivalent to charging a small capacitor) the device becomes an insulator. There is, in fact, a small leakage current caused by minority carriers described earlier. This is normally negligible.

The p-n junction thus has an asymmetrical 1/V relationship, as shown in the graph (called a characteristic) of voltage across and current through it. It can be seen that a small forward voltage is needed to start conduction. This corresponds to the charge on the depletion layer, and is about 0.2 V for germanium and 0.7 V for silicon.

In itself the p-n junction is an excellent rectifier, but it is also the basis of more complex semiconductor devices to be described in later chapters.

Resistors

Resistors are probably the widest used components in electronic circuits. They are used according to Ohm's law, namely:

Resistors are available in values from fractions of ohms to tens of megohms. As resistors pass current energy is absorbed in the form of heat, equal to I2R watts. The temperature of the resistor rises until the heat radiated equals the heat absorbed. This temperature rise determines the maximum wattage a resistor can dissipate.

The simplest (and cheapest) resistor is the carbon type. This consists of a small rod of carbon, moulded to give the required value. The carbon rod is usually mounted in a protective moulding, with connections brought out on axial leads. Carbon resistors are available from 0.125 W to 2 W ratings, and having values from a few ohms to around I MO.

The value of a resistor changes with temperature. The resistance at temperature t(0C) is given by

R1 = R20 (1 +at)

where R20 is the resistance at 20°C, and a is defined as the temperature coefficient (typically 0.01% per degree Centigrade).

Carbon resistors have a large negative temperature coefficient. The effect of thermal heating can thus become cumulative, and carbon resistors are not suitable for applications where great precision is required.

In itself the p-n junction is an excellent rectifier, but it is also the basis of more complex semiconductor devices to be described in later chapters.

Resistors

Resistors are probably the widest used components in electronic circuits. They are used according to Ohm's law, namely:

Resistors are available in values from fractions of ohms to tens of megohms. As resistors pass current energy is absorbed in the form of heat, equal to I2R watts. The temperature of the resistor rises until the heat radiated equals the heat absorbed. This temperature rise determines the maximum wattage a resistor can dissipate.

The simplest (and cheapest) resistor is the carbon type. This consists of a small rod of carbon, moulded to give the required value. The carbon rod is usually mounted in a protective moulding, with connections brought out on axial leads. Carbon resistors are available from 0.125 W to 2 W ratings, and having values from a few ohms to around I MO.

The value of a resistor changes with temperature. The resistance at temperature t(0C) is given by

R1 = R20 (1 +at)

where R20 is the resistance at 20°C, and a is defined as the temperature coefficient (typically 0.01% per degree Centigrade).

Carbon resistors have a large negative temperature coefficient. The effect of thermal heating can thus become cumulative, and carbon resistors are not suitable for applications where great precision is required.

Greater stability can be obtained from an alternative method of using the resistance of carbon. A thin film of carbon is deposited on to an insulating former, often glass. The resistance value is determined by spiral grooves cut along the body of the resistor. These resistors are called thin-film resistors, and accurate control over their construction makes them suitable for precision applica tions. Similar construction techniques are used with other resistive materials, such as metals and metallic oxides.

Where high wattage is required, it is necessary to use wire-wound resistors. The required length of thin wire is wound on to a former, then covered with a protective vitreous enamel. Care must be taken in mounting high wattage resistors onto printed circuit boards to allow free air flow and to ensure that the inherently high tempera tures do not affect adjacent components. The construction inevitably gives the resistor a large inductance. This can be reduced by use of non-inductive bifilar windings (i.e. a double spiral), but can never be completely eliminated.

Resistors are inherently 'noisy' devices; the random motion of electrons through them produces small voltage changes which are heard as a high frequency 'hiss' in audio circuits, or appears as a dither on video signals. The amplitude of the noise is related to the temperature, voltage and current, and also the type of construction of the resistor. Metallic film resistors are best suited to low noise applications. Typical noise voltages are 0.5 !J.V/V applied, for a 10 KQ resistor.

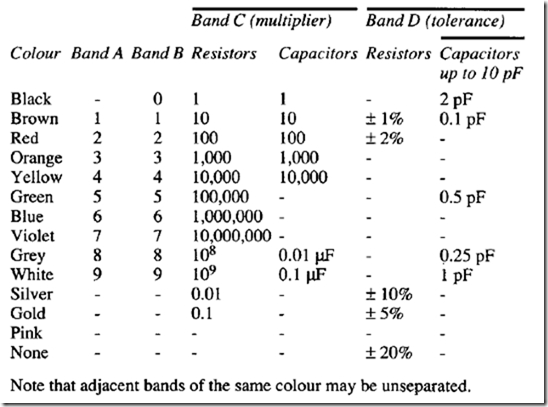

Resistors are identified by a colour code showing value and tolerance, or marked according to BS 1852. Resistor and capacitor colour coding is shown below, while markings according to BS 1852 are given over

Resistor and capacitor colour coding

Greater stability can be obtained from an alternative method of using the resistance of carbon. A thin film of carbon is deposited on to an insulating former, often glass. The resistance value is determined by spiral grooves cut along the body of the resistor. These resistors are called thin-film resistors, and accurate control over their construction makes them suitable for precision applica tions. Similar construction techniques are used with other resistive materials, such as metals and metallic oxides.

Where high wattage is required, it is necessary to use wire-wound resistors. The required length of thin wire is wound on to a former, then covered with a protective vitreous enamel. Care must be taken in mounting high wattage resistors onto printed circuit boards to allow free air flow and to ensure that the inherently high tempera tures do not affect adjacent components. The construction inevitably gives the resistor a large inductance. This can be reduced by use of non-inductive bifilar windings (i.e. a double spiral), but can never be completely eliminated.

Resistors are inherently 'noisy' devices; the random motion of electrons through them produces small voltage changes which are heard as a high frequency 'hiss' in audio circuits, or appears as a dither on video signals. The amplitude of the noise is related to the temperature, voltage and current, and also the type of construction of the resistor. Metallic film resistors are best suited to low noise applications. Typical noise voltages are 0.5 !J.V/V applied, for a 10 KQ resistor.

Resistors are identified by a colour code showing value and tolerance, or marked according to BS 1852. Resistor and capacitor colour coding is shown below, while markings according to BS 1852 are given over

Resistor and capacitor colour coding

Comments

Post a Comment